Our Solution

Tailoring Data Experiences for Team Success

Define ambitious benchmarks for the future mobility that challenges your team to strive for excellence.

Trusted by Top Brands

About us

A connected Data Platform for all automotive controls and test verticals

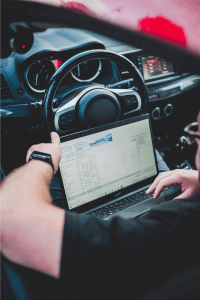

- Purpose built to help engineers accelerate vehicle validation processes, Drivetech’s solutions enable you to overcome data bottlenecks, analysis oversights, human errors to uncover data patterns & deep insights with the power of AI driven data processes.

- DriveTech’s SierraDT IVN Interface unlocks edge processing powered by high speed data capture with unmatched remote diagnostic capabilities.

- The StellarAi Enterprise Data Platform helps you and all your team members to collaborate in place & consume all types of vehicle validation data effectively & intelligently with minimum manual intervention required .

Applications:

Software Define Vehicles

End of Line Testing

Developing AI/ML Models

Connected Vehicles

- Indoor and Outdoor Vehicle Testing

Service Oriented Vehicle Diagnostics (SoVD)

HIL Testing

News & Blogs

Stay Ahead: Trends & Strategies

Elevating Test Data Quality Checks with StellarAi

In the dynamic landscape of automotive testing, data integrity is paramount...

Intelligent Reporting with StellarAi

Data analysis often falls short of its intended value unless it's documented in a report.

Learn , Connect & Innovate

Be Part of the Future Tech Revolution

Immerse yourself in the world of future technology. Explore our comprehensive resources, connect with fellow tech enthusiasts, and drive innovation in the industry. Join a dynamic community of forward-thinkers.